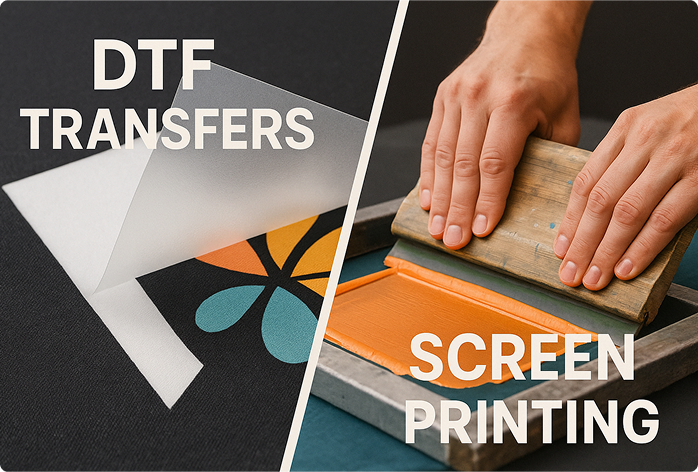

Screen Printing vs. DTF Transfers – A Complete Guide for Custom Apparel in Katy, Texas

In the world of custom t-shirt design, two methods dominate: screen printing and DTF (Direct-to-Film) transfers. For years, screen printing was the go-to for bulk orders and bold designs. Today, though, DTF has emerged as a modern solution offering more flexibility, especially for smaller batches and intricate designs.At Shirt Printing Center in Katy, Texas, we’ve worked with both techniques and understand their pros, cons, and best uses. This article will take a deep dive into each method—explaining how they work, what they cost, and which one is best for your needs. Whether you're printing one shirt or one thousand, you'll walk away with the knowledge to make the right choice.

Screen Printing: The Time-Tested Classic

Screen printing is one of the most popular and enduring methods of decorating garments. It’s especially favored for high-volume orders where bright, bold, long-lasting prints are required. Before we explore the technical details, it's important to understand why screen printing has been the industry standard for so long. This method uses mesh screens and thick, opaque inks that bond well with fabric. It delivers vivid colors and strong prints that can last for years—even through heavy use and frequent washing. From local sports uniforms to major fashion runs, screen printing remains a staple because of its cost efficiency at scale, visual consistency, and professional finish. Let’s break down how screen printing works and what makes it so effective.

Screen printing is a manual or semi-automated process that involves pressing ink through a fine mesh screen onto fabric. Each screen acts like a stencil, with different parts of the mesh blocked out so ink can only pass through where the design is meant to appear.Each color in a design needs its own screen, which is why multi-color artwork requires more setup, more time, and more cost.

Here’s a simplified step-by-step of the screen printing process:

- Design Separation – The original artwork is split by color into separate files.

- Screen Creation – Each color is burned into its own screen using light-reactive emulsion.

- Ink Application – A squeegee presses ink through the screen onto the shirt.

- Drying/Curing – The shirt passes through a high-temperature dryer to cure the ink and ensure durability.

This process allows screen printing shops to produce hundreds of shirts per hour once the setup is complete—making it highly efficient for bulk orders.

Materials and Equipment Used in Screen Printing

Before you can start screen printing, you need the right tools and materials. This method isn’t just about ink and shirts—it involves specialized supplies that affect the quality of your print.

This section introduces the screen printing equipment and materials necessary to run a print job, either professionally or at home.

At the heart of screen printing are the mesh screens, often referred to as screen printing screens. These are typically made from polyester and stretched over a rigid frame. The mesh count (or number of threads per inch) affects the level of detail and ink thickness.

Lower mesh counts are used for thick inks or bold designs; higher mesh counts are for fine lines and smaller details.

Though once made with silk, today’s “silk screens” are synthetic but the process still goes by the name. Essential equipment includes:

Squeegees for spreading ink

Flash dryers for curing

Exposure units for burning the stencil onto the screen

Inks (plastisol for boldness, or water-based for eco-friendliness)

T-shirt pallets for holding garments in place

For those in Katy, Texas looking to try it themselves, we’re often asked: “Where can I find screen printing supplies near me?”—and we’re happy to connect you with trusted local vendors or offer in-house print runs at Shirt Printing Center.

The Strengths and Weaknesses of Screen Printing

Now that you understand how it works and what it needs, let’s quickly summarize why people choose (or avoid) screen printing.

- Extremely durable and wash-resistant

- Vibrant and bold colors

- Ideal for printing hundreds or thousands of shirts

- Great for designs with 1–3 colors

- Not ideal for detailed, photo-realistic designs

- High setup cost for small runs

- Long prep time per job

DTF (Direct-to-Film): The Future of Custom Printing

DTF printing is a revolutionary approach to fabric decoration. Unlike screen printing, DTF is entirely digital, removing the need for physical screens. It prints directly onto a special film, which is then heat-transferred to fabric.

This section explains how DTF works, what it offers, and why it's gaining popularity—especially for creative entrepreneurs and small businesses in Katy, TX.

DTF (Direct-to-Film): The Future of Custom Printing

DTF printing is a revolutionary approach to fabric decoration. Unlike screen printing, DTF is entirely digital, removing the need for physical screens. It prints directly onto a special film, which is then heat-transferred to fabric.

This section explains how DTF works, what it offers, and why it's gaining popularity—especially for creative entrepreneurs and small businesses in Katy, TX.

DTF stands for Direct-to-Film, and it involves printing a digital image onto a transparent PET film using specialized ink. After applying a heat-activated adhesive powder, the print is cured and then pressed onto a garment using a heat press.

This method allows for unlimited colors, photo-quality images, and excellent stretchability, even on polyester or performance wear.

Here’s how DTF printing unfolds:

Design Creation – A digital file is created in full color.

1. Film Printing – The image is printed on a special film with CMYK and white inks.

2.Powder Application – The design is dusted with hot-melt adhesive powder.

3.Curing – The film is dried using heat to activate the adhesive.

4.Heat Transfer – The film is pressed onto the shirt using a heat press.

5.Cold Peel – Once cooled, the film is peeled off, leaving a vivid, permanent design.

Why People in Katy Are Choosing DTF Over Screen Printing

At Shirt Printing Center, more and more clients—especially artists, influencers, and small shop owners—are choosing DTF for the following reasons:

One-off or low quantity orders are no problem

- Perfect for multi-color and photo-quality designs

- No screen setup = faster turnaround

- Print on anything: cotton, polyester, nylon, blends, spandex

- With no minimum order and stunning results, DTF is becoming the go-to for custom t-shirts, hoodies, kidswear, hats, and even bags.

With no minimum order and stunning results, DTF is becoming the go-to for custom t-shirts, hoodies, kidswear, hats, and even bags.

Screen Printing Vs. DTF: Detailed Comparison

Now that we’ve fully explored both printing techniques, let’s compare them across key categories.

| Category | Screen Printing | DTF Transfer |

|---|---|---|

| Setup Time | High (screens needed) | Low (digital) |

| Best For | Large runs (50+) | Small runs (1-50) |

| Color Range | Limited per screen | Unlimited full-color |

| Detail/Photo Print | Not ideal | Excellent |

| Fabrics Supported | Mostly cotton | Cotton, poly, blends, nylon |

| Durability | Very high | High (if washed cold) |

| Turnaround Speed | Slower for short runs | Fast for all orders |

Which Printing Method Is Right for You?

Choosing between screen printing and DTF comes down to your goals:

- Go with screen printing if you’re placing a bulk order of 50+ shirts with a simple design.

- Choose DTF if you want fast, full-color prints for small orders—or if your design is photo-based or highly detailed.

At Shirt Printing Center in Katy, we specialize in both. We’re always happy to consult and help you decide which printing process will save you money while delivering the best possible result.

Conclusion: DTF Is the Game-Changer, But Screen Printing Still Rules for Bulk

Screen printing is legendary—and for good reason. It’s durable, consistent, and perfect for high-volume orders. But DTF is revolutionizing the industry by opening up possibilities that screen printing can’t easily match: low cost for small runs, full-color images, and fabric versatility.

Need 200 shirts with one logo? Go with screen printing.

Want 20 unique, full-color shirts? DTF is your answer.

And the best part? You don’t have to decide alone. At Shirt Printing Center, we’ll help you evaluate your project and choose the right solution—serving Katy, Texas and beyond with top-quality custom apparel.

FAQs

Both methods are durable. Screen printing may last slightly longer through repeated washes, but DTF also holds up well when garments are washed in cold water and inside out.

Yes! DTF is perfect for individual orders or samples, with no minimum quantity required.

Both work well, but DTF often handles dark or synthetic fabrics more easily due to its adhesive powder.

For small orders, DTF is more cost-effective. Screen printing becomes cheaper only when ordering in large quantities due to setup time.

You can visit Shirt Printing Center in Katy, TX, for both services—plus expert advice on which one is best for your project.